Top 5 Myths About Thermal Imaging in Machinery Maintenance

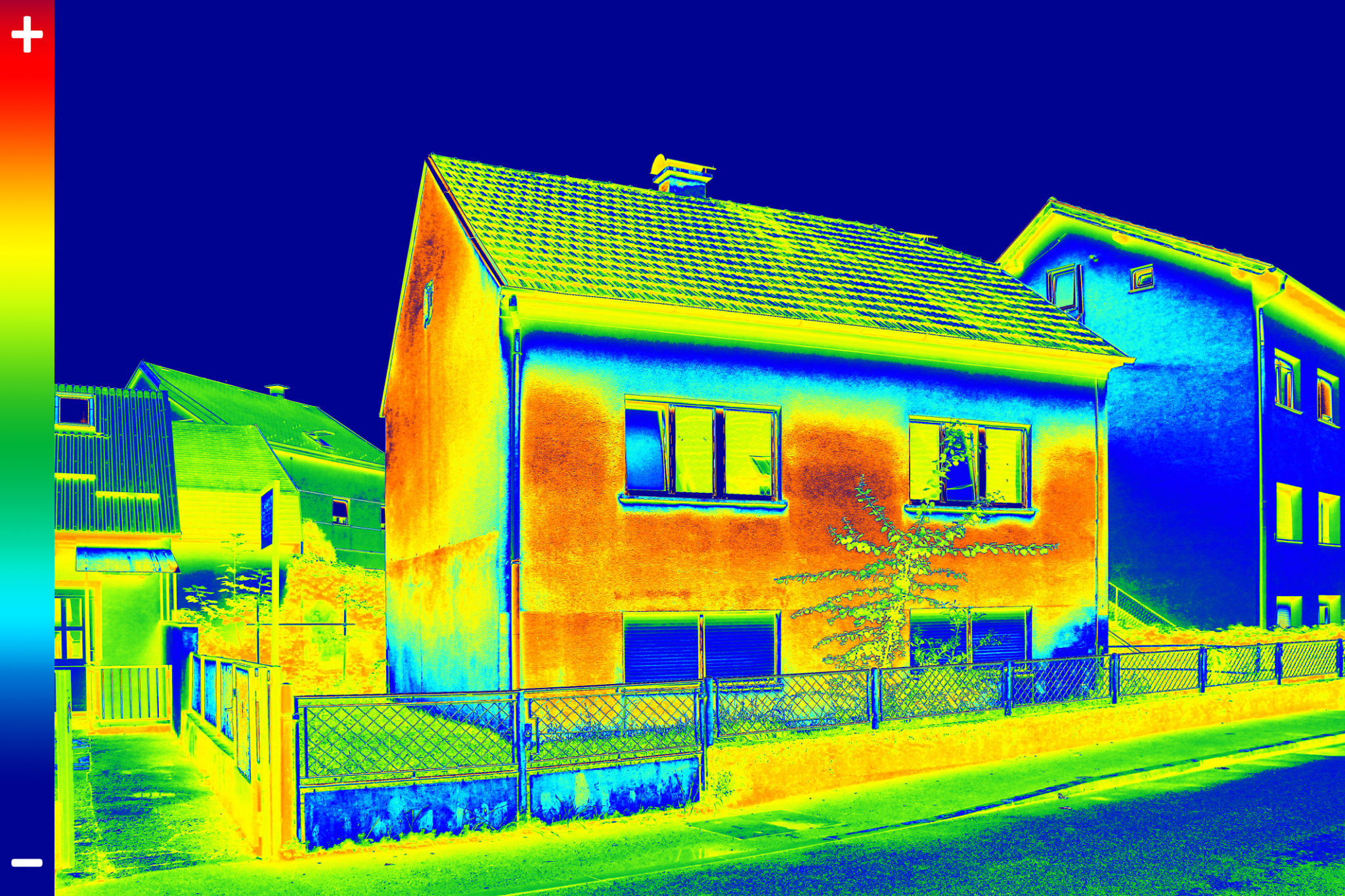

Understanding Thermal Imaging in Machinery Maintenance

Thermal imaging is becoming an essential tool in the equipment maintenance sector, offering numerous advantages for identifying and resolving issues. However, several myths surrounding its use may deter some businesses from fully utilizing this technology. This blog post will explore and debunk the top five myths about thermal imaging in machinery maintenance.

Myth 1: Thermal Imaging is Only for Large-Scale Industries

A common misconception is that thermal imaging is exclusively beneficial for large-scale industries with extensive equipment fleets. In reality, thermal imaging is versatile and can be applied to any size of operation. From small workshops to large manufacturing plants, thermal imaging helps detect problems early, preventing costly downtime and repairs.

Small businesses can benefit significantly from the proactive maintenance approach that thermal imaging provides, ensuring they sustain productivity and efficiency without the need for expensive interventions.

Myth 2: It's Too Expensive to Implement

Many believe that incorporating thermal imaging into their maintenance routine is prohibitively expensive. While it's true that initial investments are required for equipment and training, the long-term savings often outweigh these costs. Thermal imaging helps identify issues before they become major problems, reducing repair costs and extending equipment life.

Additionally, as technology advances, the cost of thermal imaging devices has decreased, making it more accessible to businesses of all sizes.

Myth 3: Thermal Imaging Requires Specialized Skills

Another myth is that specialized training and skills are mandatory to use thermal imaging effectively. Though some level of training is beneficial to interpret images accurately, many modern thermal imaging tools are designed with user-friendly interfaces.

Operators with basic training can quickly learn to capture and interpret thermal images, allowing them to make informed decisions about equipment maintenance without needing extensive expertise.

Myth 4: It's Only Useful for Electrical Inspections

A prevalent myth is that thermal imaging is only useful for electrical inspections. While it is highly effective in this area, its applications extend far beyond just electrical systems. Thermal imaging can be used for mechanical inspections, detecting issues like overheating bearings, misaligned components, and even fluid leaks.

This versatility makes it an invaluable tool in a comprehensive predictive maintenance strategy, providing insights across various types of machinery and systems.

Myth 5: Thermal Imaging Provides Instant Solutions

Finally, there's a misconception that thermal imaging gives instant solutions to machinery problems. While it indeed offers quick identification of potential issues, it's important to understand that it acts as a diagnostic tool rather than a fix.

The information gathered through thermal imaging should be used alongside other diagnostic tools and expertise to develop a comprehensive maintenance plan. This combined approach ensures that identified issues are addressed effectively and efficiently.

In conclusion, debunking these myths can help businesses of all sizes embrace the benefits of thermal imaging. By investing in this technology, companies can enhance their maintenance strategies, leading to improved equipment reliability and reduced operational costs.