Understanding Infrared Services for Industrial Maintenance

Understanding Infrared Services for Industrial Maintenance

In today's fast-paced industrial environment, maintaining the health and efficiency of machinery is crucial. One of the most effective tools for proactive maintenance is infrared (IR) technology. This non-invasive technique allows for the detection of potential issues before they lead to costly breakdowns. Understanding how infrared services work and their benefits can help industries save time and money.

What Are Infrared Services?

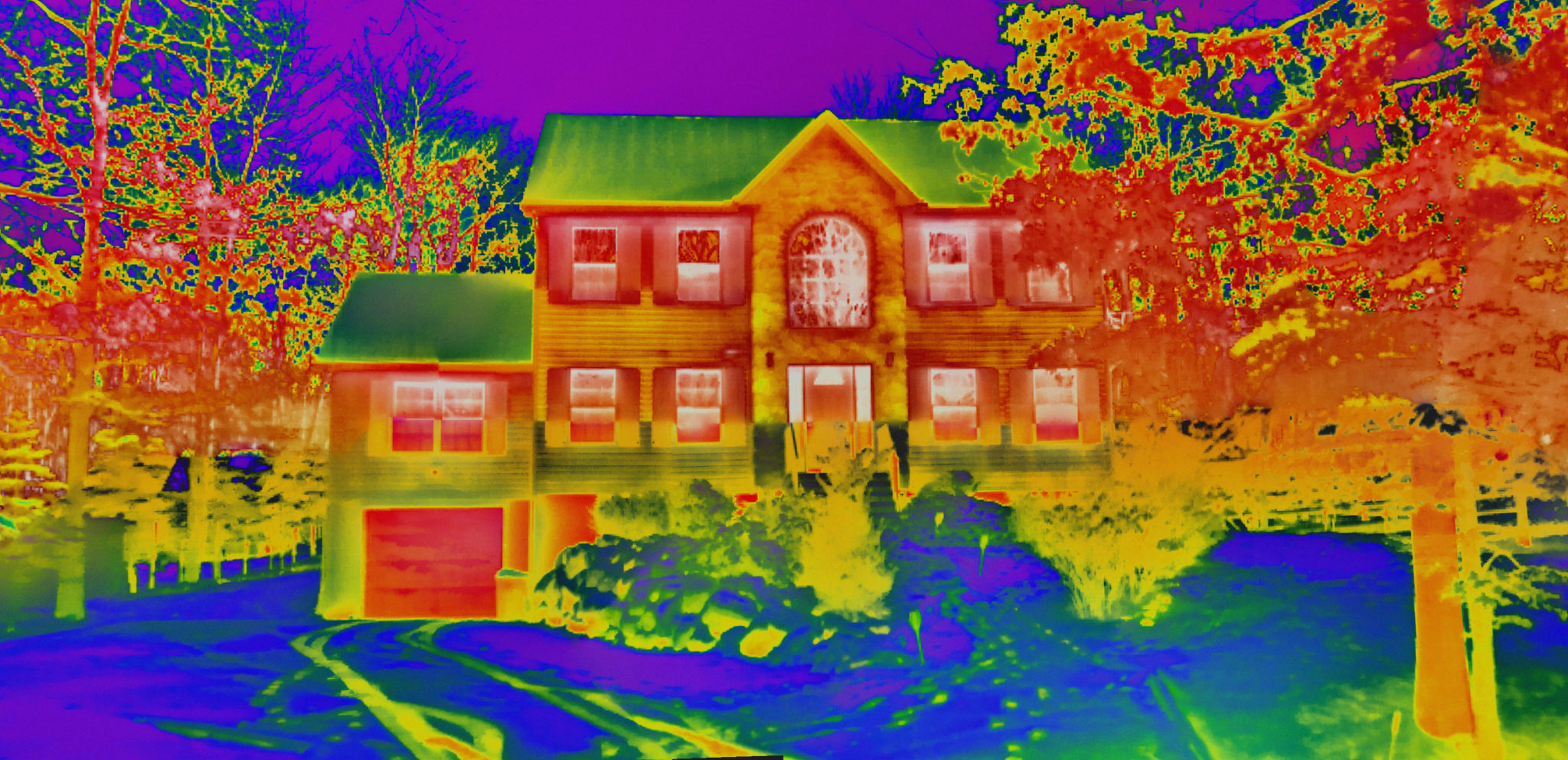

Infrared services involve the use of thermal imaging cameras to detect heat patterns emitted by equipment and systems. These cameras convert infrared radiation into visible images that display temperature variations. This technology enables maintenance teams to identify abnormal heat signatures, which often indicate problems such as electrical faults, mechanical failures, or insulation breakdowns.

By capturing these images, technicians can pinpoint areas that require attention, allowing for timely interventions. This proactive approach can significantly reduce the risk of unexpected failures and extend the lifespan of equipment.

Benefits of Infrared Technology in Maintenance

One of the primary advantages of using infrared services is the ability to conduct inspections without interrupting operations. Since thermal imaging is non-contact and non-destructive, it allows for continuous monitoring of critical systems without any downtime. This capability is particularly beneficial in industries where machinery must run 24/7.

Another significant benefit is the early detection of potential issues. Infrared technology can identify problems such as overheating motors, loose electrical connections, and worn bearings before they escalate into major failures. This early intervention can help avoid costly repairs and minimize production losses.

Key Applications of Infrared Services

Infrared services are versatile and can be applied across various sectors. In the electrical field, they are used to inspect switchgear, transformers, and circuit breakers to ensure optimal performance. Mechanical systems also benefit from IR inspections, particularly in identifying misalignments or friction issues in rotating equipment.

Additionally, infrared technology plays a vital role in building inspections by detecting insulation deficiencies, air leaks, and moisture intrusion. This comprehensive application makes it a valuable tool for maintaining both equipment and infrastructure.

Implementing an Infrared Maintenance Plan

To leverage the full potential of infrared services, it's essential to integrate them into a regular maintenance plan. A structured approach involves scheduling routine inspections, analyzing thermal images, and documenting findings for future reference. Companies can also train their maintenance staff to interpret thermal data effectively or hire specialized service providers for this task.

Moreover, investing in quality infrared cameras and related software can enhance the accuracy and efficiency of inspections. By prioritizing these technologies, businesses can ensure a safer and more reliable operational environment.

Conclusion

Infrared services have become an indispensable part of industrial maintenance strategies. By providing real-time insights into equipment health, they empower businesses to act swiftly and avoid unexpected downtimes. Whether used for electrical systems, mechanical components, or building inspections, infrared technology offers a proactive solution to maintenance challenges.

As industries continue to evolve, staying ahead with innovative tools like infrared technology will be key to maintaining operational excellence and competitiveness in the market.